Leading Manufacturer of Frosted Polycarbonate in China

Best Frosted Polycarbonate You Could Find In China

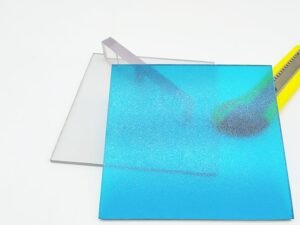

Frosted Polycarbonate sheet Introduction

Frosted polycarbonate sheet is also called “Frosted Plastic Sheet” or “Matte Polycarbonate“, which is the right material mainly to add privacy and scratch resistance in office/home applications and printing products. It is also the best material for home decoration applications including printing products, shower enclosure, carport roof, office dividers between rooms, and skylight roof, because of the privacy matte patterns, which is to conceal something on the backface.

Specification Of Frosted Polycarbonate Sheet

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Deflection Temperature (264 psi load) | ASTM D648 | °F/°C | 275/135 |

| Vicat Softening Point | ASTM D1525 | °F/°C | 284/140 |

| Maximum Continuous Service Temperature | — | °F/°C | 190/87 |

| Maximum Discontinuous Service Temperature | — | °F/°C | 210/98 |

Main Benefits Of Frosted Polycarbonate Sheet

- Printable Frosted Polycarbonate, thickness from 0.075mm to 0.7mm;

- Frosted Polycarbonate Sheet, thickness from 1mm to 20mm;

- Excellent Printing Performance, it is totally printing-grade polycarbonate;

- Great wear-resisting property and flammability;

- Specifically designed to help eliminate pinholes in demanding backlit application;

- With UV Coating Layer, the lifespan is more than 10 years;

- Custom colors of frosted polycarbonate sheets are available;

- Withstands most extreme hot and cold climates between -40°C to 120 °C;

- Cutting to size service is available;

- Fast Delivery, normal leading time will be one or two weeks;

Typical Applications

Our main products are PVC roof sheets, Polycarbonate Sheets, FRP sheets, etc.

Of course, we can send you our samples for free. We only need your courier Number.

The thickness of PVC roof tiles may vary, but common thickness ranges are between 2.0mm and 3.0mm. The specific thickness depends on the design and usage requirements of the product.

PVC roof tiles are usually available in a variety of colors, such as white, blue, green, red, brick red, gray, yellow, etc., to suit different architectural styles and aesthetic needs.

We have our own design department and provide design services to thousands of partners.

we are factory

Yes, although PVC roof tiles have a long service life and good durability, they still need regular maintenance and care. This includes clearing debris from the roof and checking whether the tiles are damaged or loose.

When cleaning PVC roof tiles, avoid using sharp or hard tools to scratch the surface to avoid damaging the tiles. You can use a soft brush or a high-pressure water gun for cleaning, but be careful not to use too much water pressure to avoid damaging the tiles or affecting their waterproof performance.