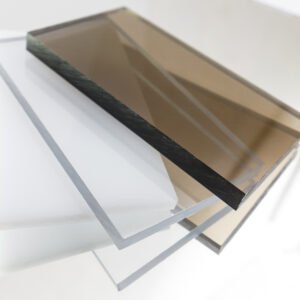

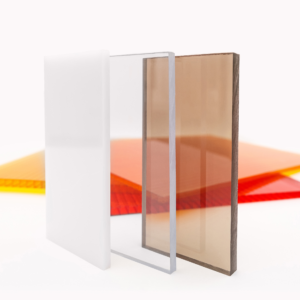

Acrylic and polycarbonate sheets are popular materials in the market because of their similar appearance. They are the most commonly used transparent plastic materials in the market. However, both have advantages and disadvantages. Knowing the advantages and disadvantages of acrylic sheets and polycarbonate sheets will help you choose the most suitable sheet for your specific project. In this blog, we will compare these two plastics.

1. Introduction of acrylic and polycarbonate sheets

Acrylic sheets, also known as acrylic sheets, are colorless, transparent, light-resistant, and aging-resistant materials made from the polymerization of acrylic acid or methacrylic acid and its esters or other derivatives.

Polycarbonate sheets, also known as polycarbonate sheets, are high-performance plastic sheets with many excellent properties.

2. Advantages and disadvantages of acrylic and polycarbonate sheets

Acrylic sheets and polycarbonate sheets are two common plastic materials that are widely used in many fields, but they also have their advantages and disadvantages. The following table lists the advantages and disadvantages of acrylic and polycarbonate sheets.

Acrylic or Plexiglass Sheeting | ||

Pros | · Easier to machine than polycarbonate · Can be polished, both for scratches and clean edges · Better glue bonding · Shinier · Less expensive than polycarbonate by as much as 35%

| · Greater strength than acrylic · More flexible than acrylic; can be shaped at room temperature · Can be exposed to high temperatures and is non-flammable · Highly resistant to chemicals · Can be drilled without cracking · Lighter in weight than comparable acrylic

|

Cons | · More rigid · More likely to crack during drilling or upon impact · More likely to chip · Should not be exposed to open flames

| · Scratches easily · Cannot be polished · Can be dented easily · More translucent than transparent as compared to acrylic |

3. Application of acrylic and polycarbonate sheets

Acrylic sheets and Polycarbonate sheets are two high-performance transparent plastic materials that are widely used in many fields such as architecture, advertising, transportation, and medicine.

Uses of Acrylic Sheets:

- Retail display cabinets

- Lighting

- Transparent shelves for brochures or printed materials

- Indoor and outdoor signage

Uses of Polycarbonate Sheets:

- Protective equipment

Bulletproof “glass” - windows and doors

- Windshields of various vehicles

- Monitor screen protector

4. Cost comparison of acrylic and polycarbonate sheets

In terms of cost comparison, acrylic is often seen as a cheaper alternative to polycarbonate. The relatively simple raw material cost and production process of acrylic resin make its overall cost lower. In addition, acrylic resin has better processing performance, which makes it easy to manufacture products of various shapes and sizes.

However, polycarbonate occupies an important position in fields that require high-performance materials due to its excellent strength, durability and impact resistance. Although these advantages make polycarbonate relatively expensive to manufacture, the long-term durability and protection it provides often make it a long-term solution worth investing in.

In contrast, although acrylic resin is lower in cost and more economical to replace, its fragility is a disadvantage that cannot be ignored. In application environments that need to withstand high impact or pressure, acrylic resin may not be the best choice.

In summary, the choice between acrylic and polycarbonate should be considered comprehensively based on the specific application scenario, performance requirements and cost budget. Acrylic is an affordable choice in cost-sensitive occasions where material performance requirements are not particularly high; while polycarbonate may be a more suitable material in environments that require high strength and high durability.

5.How to choose acrylic and polycarbonate sheets

When choosing between Acrylic Sheets and Polycarbonate Sheets, there are several factors to consider, including performance characteristics, cost, application scenarios, and the specific needs of individuals or projects.

When looking for transparent sheets with innovative performance and a wide range of uses, polycarbonate sheets and acrylic sheets are undoubtedly the best choice over traditional glass and other transparent materials. In order to meet your diverse needs for these two high-performance materials, it is particularly important to choose a reliable plastic distributor. Langfang Bonai is your ideal partner. We focus on providing high-quality polycarbonate from top manufacturers in the industry.

We not only ensure the excellent quality of the materials but also provide a comprehensive range of manufacturing and customization services. No matter what specific requirements you have for the size, transparency, strength, or durability of the sheet, Langfang Bonai can accurately meet them to ensure that the final product perfectly fits your application scenario and expected effect. With our professional solutions, you can easily get the polycarbonate that best suits your project needs, adding unlimited possibilities to your project.