Professional Polycarbonate Sheets solutions

We provide high-quality PCB products to global customers, covering various types such as polycarbonate sheets, solid polycarbonate sheets, and PC roofing sheets, which are widely used in construction, industry, agriculture and other fields.

Our products

We offer a variety of specifications and types of polycarbonate sheets to meet the needs of different application scenarios.

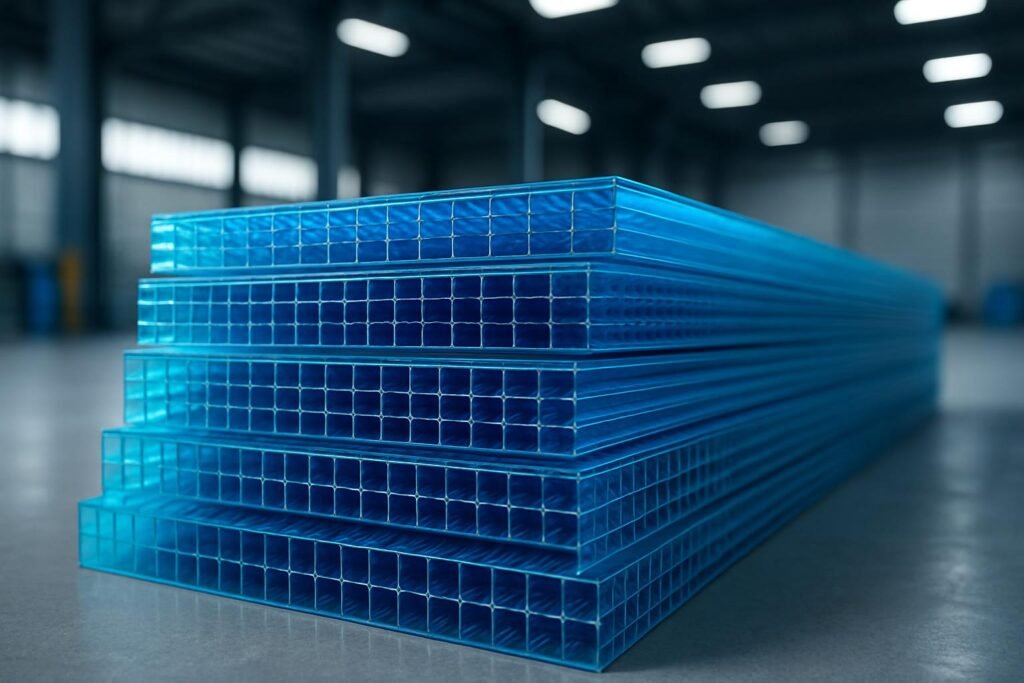

Polycarbonate sheets

With excellent heat insulation, sound insulation, and thermal insulation properties, they are widely used in greenhouses, awnings, and other similar applications.

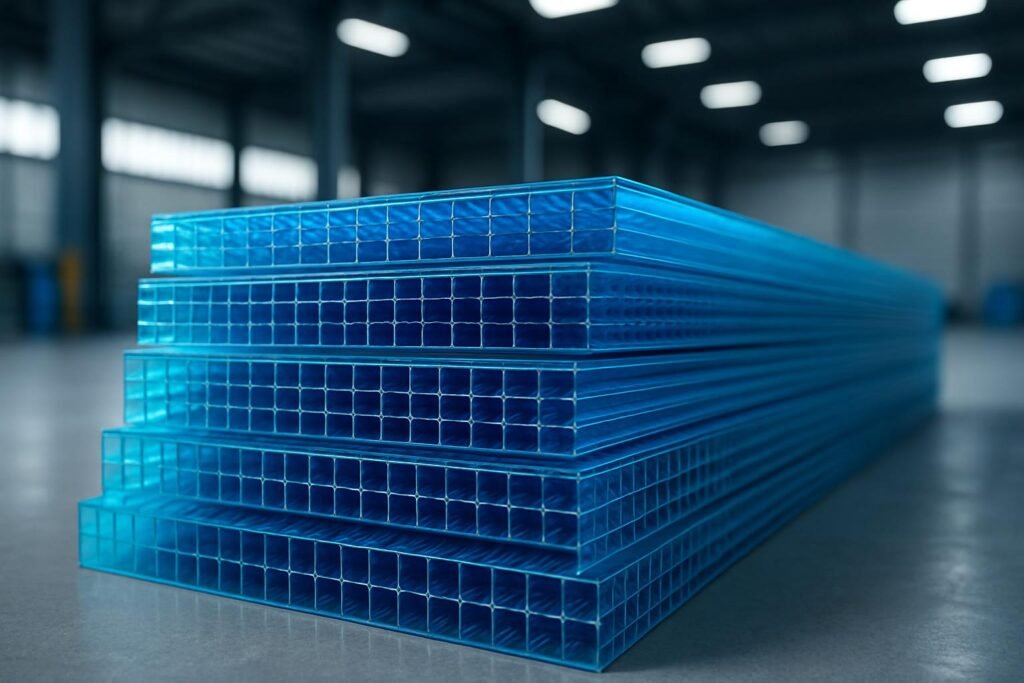

polycarbonate solid sheet

With its extremely strong impact resistance and weather resistance, it is suitable for high-intensity applications such as protection and windows.

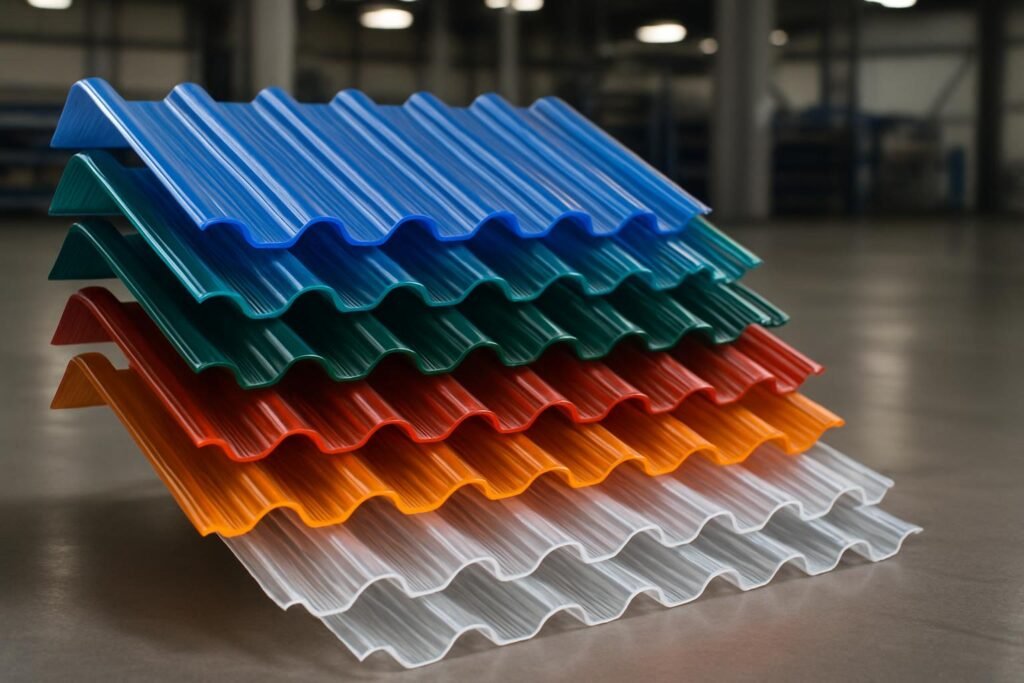

PC Tiles

Waterproof, heat-insulating, and lightweight corrugated structures are an ideal choice for roofing materials.

Why Choose Us

Years of industry experience, professional products and services.

Quality Assurance

Complies with international standards such as ISO 11963 and GB/T 44570, ensuring reliable quality.

High performance

Its impact strength is about 30 times that of propylene, and it has excellent heat and cold resistance.

Environmentally friendly and sustainable

100% recyclable materials, meets environmental protection requirements, and utilizes green production processes.

Customization services

Supports various specifications, colors, and surface treatments to meet individual needs..

Product Specifications Comparison

Quickly understand the technical specifications and application characteristics of different products

| Specifications | polycarbonate sheet | polycarbonate solid sheet | PC Tiles |

| Thickness | 4-20mm | 2-10mm | 1.0-1.5mm |

| Light transmittance | 75-90% | 85-92% | 80-88% |

| Impact resistance | high | Extremely high | medium |

| Thermal insulation performance | Excellent | generally | Excellent |

| Main applications | Awnings and greenhouses | Protection, Windows | Roof Covering |

Application

Polycarbonate sheets are widely used in many industries and fields.

Architectural field

- Greenhouse

- Awning/Sunshade

- Skylight

- Soundproof Wall

Industrial applications

- Machine protection

- Industrial windows

- Protective barriers

- Equipment covers

Agriculture

- Greenhouse facilities

- Greenhouse covering

- Agricultural sheds

- Protective covers

Case

Real-world project examples demonstrate the value of our products.

Modern greenhouse project

By using multi-layered hollow polycarbonate panels, year-round constant temperature control is achieved, increasing vegetable yield by 30%.

Return on investment increased by 25%

Industrial Protective Barrier Applications

Using polycarbonate sheets to manufacture machine protective covers effectively protects worker safety and reduces accident rates.

The accident rate decreased by 40%.

Roofing Renovation Project

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Energy costs reduced by 35%

Customer Reviews

Listen to what our customers have to say

FAQ

Quickly learn about frequently asked questions about our products

What is the lifespan of polycarbonate sheets?

Under normal use conditions, our polycarbonate sheets have a lifespan of 10-15 years. Products equipped with a UV protective layer perform even more stably in outdoor environments.

How to choose the right board thickness?

Choosing the right thickness requires considering the application scenario, load-bearing requirements, and budget. Generally, 4-6mm is recommended for greenhouses, and 6-10mm is recommended for industrial protection.

Do you offer customization services?

Yes, we offer customization services with a variety of sizes, colors, and surface finishes to meet specific application needs.

Need a customized solution?

Our professional team can provide customized Polycarbonate Sheet solutions based on your specific needs.