Leading Honeycomb Polycarbonate Sheet Manufacturer In China

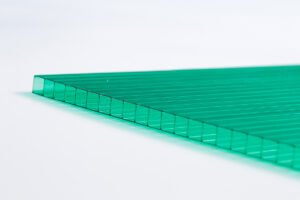

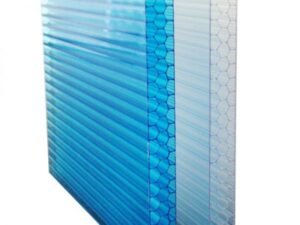

Honeycomb Polycarbonate sheet is one of the topic multiwall polycarbonate sheets. As the best plastic honeycomb panels, it offers a honeycomb type profile that creates an insulating air space, therefore, the honeycomb polycarbonate panel offers a really high thermal isolation characteristic and high impact resistance. The clear honeycomb polycarbonate sheet is high transparency from 50%-70%.

Honeycomb Polycarbonate Specification

| Physical Property | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Light transmittance | D-1003 | % | >76 |

| Heat deflection temperature (HDT) | D-648 | °C | 140 |

| Service Temperature – Short term | °C | -50 to +120 | |

| Service Temperature – Long term | °C | -40 to +100 | |

| Impact falling dart | ISO 6603/1 | J | 40-400 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Practical thermal expansion/contraction | mm/m | 3 |

Stadium Roofing

With the excellent impact resistance, multiwall polycarbonate sheet is the best choice for stadium roofing, even under the storm, hailstone, heavy snowfall, sandstorm, hurricane weather, and intense ultraviolet condition.

Skylight of warehouse

Honeycomb polycarbonate sheet is lighter weight but offers high impact resistance, it is a great choice for the skylight.

Main Benefits of Honeycomb Polycarbonate Sheet

- Honeycomb Polycarbonate Sheet is really lighter weight than Solid Polycarbonate Sheet;

- It is stronger than twin wall polycarbonate sheet;

- Easy to cut to size and install on building roof;

- Excellent thermal insulation and sound insulation;

- With UV Coating Layer, the lifespan is more than 10 years;

- Withstands most extreme hot and cold climates between -40°C to 120 °C;

- Anti-condensation Coating Layer is on inside surface for greenhouse application;

- Machining polycarbonate service is available;

Related Products

Frequently Asked Questions

Our main products are PVC roof sheets, Polycarbonate Sheets, FRP sheets, etc.

Of course, we can send you our samples for free. We only need your courier Number.

The thickness of PVC roof tiles may vary, but common thickness ranges are between 2.0mm and 3.0mm. The specific thickness depends on the design and usage requirements of the product.

PVC roof tiles are usually available in a variety of colors, such as white, blue, green, red, brick red, gray, yellow, etc., to suit different architectural styles and aesthetic needs.

We have our own design department and provide design services to thousands of partners.

we are factory

Yes, although PVC roof tiles have a long service life and good durability, they still need regular maintenance and care. This includes clearing debris from the roof and checking whether the tiles are damaged or loose.

When cleaning PVC roof tiles, avoid using sharp or hard tools to scratch the surface to avoid damaging the tiles. You can use a soft brush or a high-pressure water gun for cleaning, but be careful not to use too much water pressure to avoid damaging the tiles or affecting their waterproof performance.